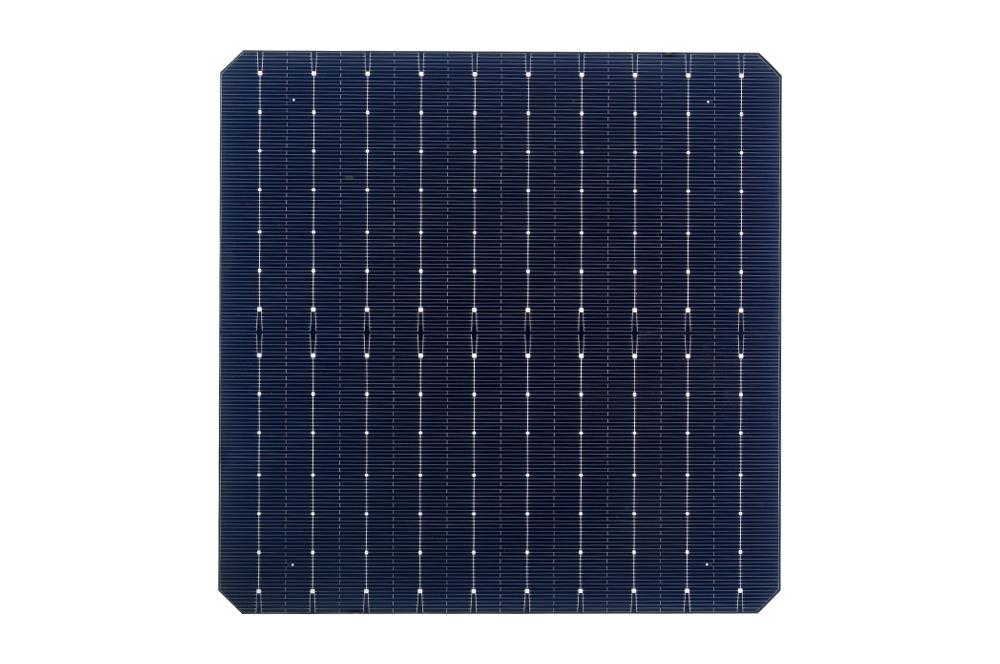

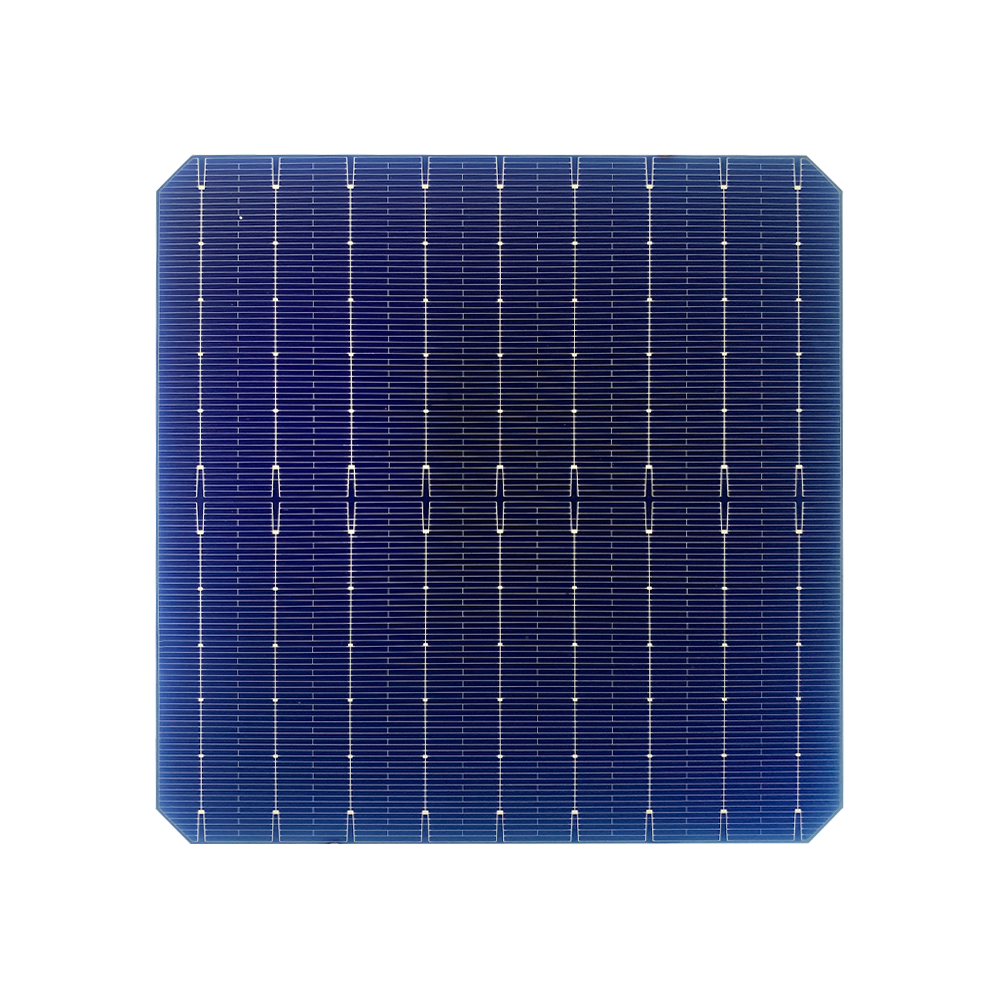

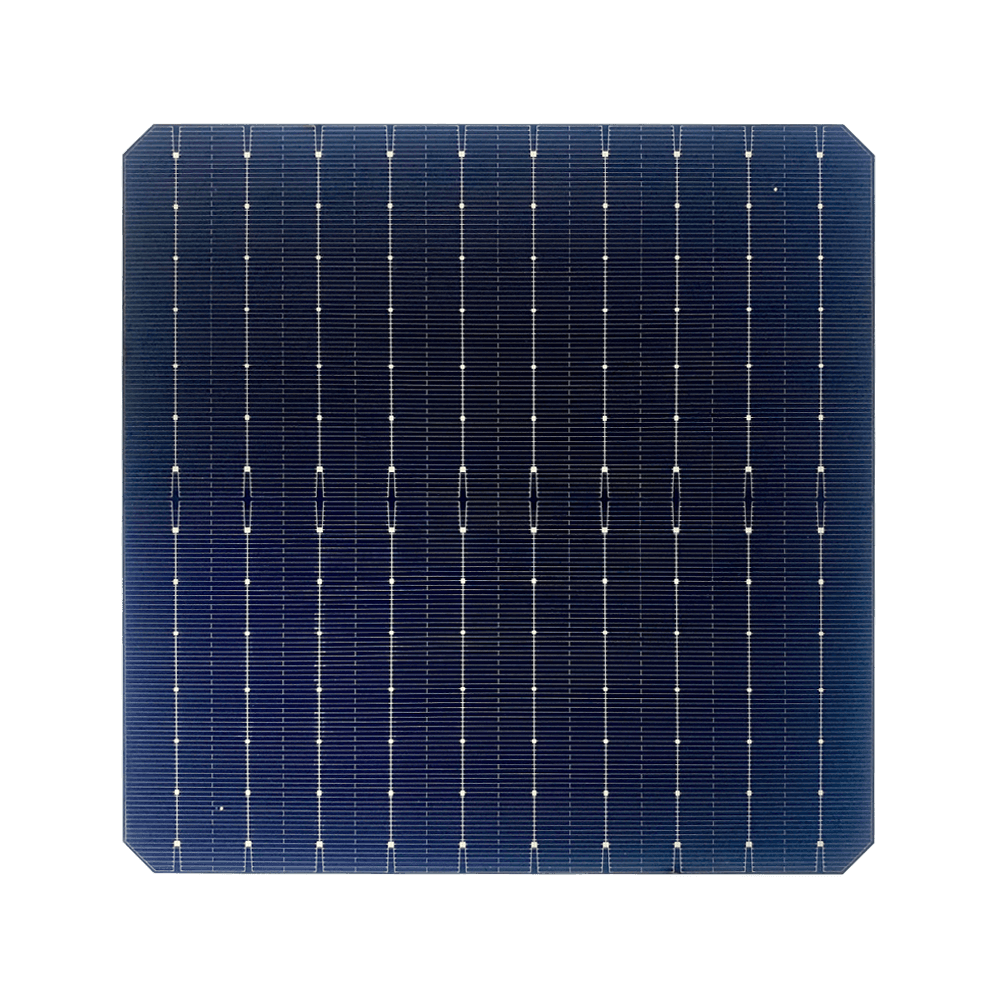

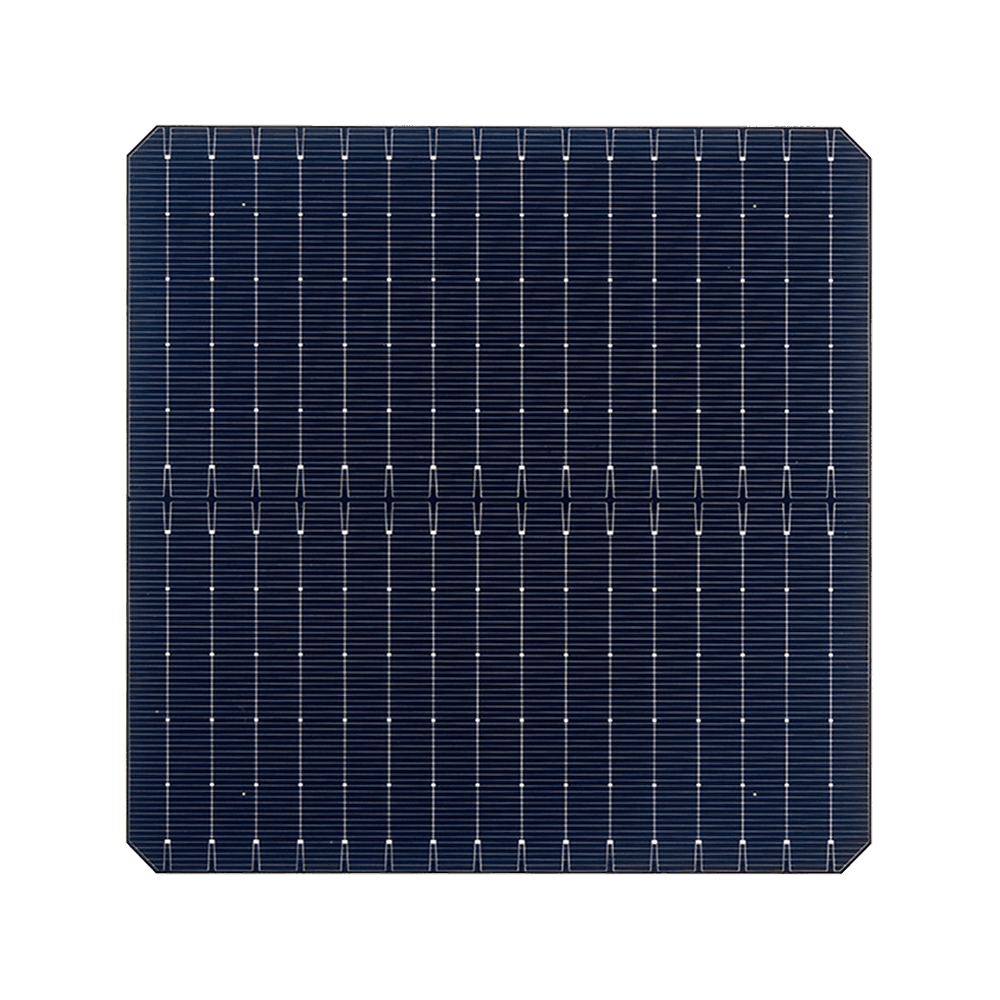

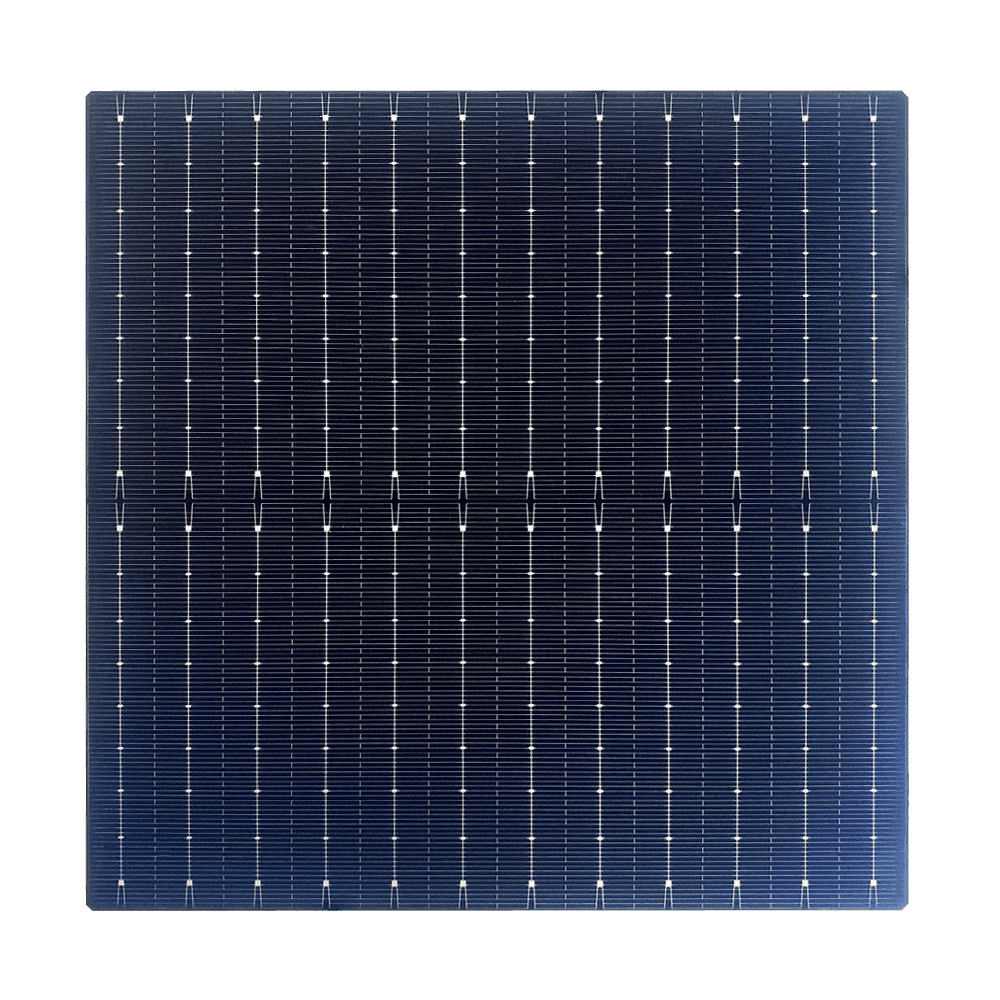

Monocrystalline silicon solar cells are highly regarded for their superior energy conversion efficiency and have become leaders in the solar industry. The fundamental reason for this high efficiency lies in the crystal structure of single-crystal silicon. Monocrystalline silicon is produced by pulling crystals from high-purity silicon rods, forming a uniform, continuous crystal structure that facilitates the flow of electrons. Under the influence of light, single crystal silicon can capture and conduct electrons more effectively, thereby improving the energy conversion efficiency of the battery.

Specifically, monocrystalline silicon solar cells are typically capable of achieving energy conversion efficiencies of over 20%, making them among the most efficient solar cells on the market. This is higher than other solar cell technologies such as polycrystalline silicon and amorphous silicon. In practical applications, this means that monocrystalline silicon solar cells can generate more power under the same lighting conditions, providing users with higher power generation performance.

Monocrystalline silicon solar cells are also highly adaptable to high-temperature environments and exhibit stable performance. This is particularly important in practical applications, especially in climates with high temperatures in summer. Therefore, choosing monocrystalline silicon solar cells means choosing an efficient and reliable solar solution, bringing users better return on investment and long-lasting performance.

The process of manufacturing monocrystalline silicon solar cells is a highly complex and technology-intensive process. First, the first step in the manufacturing process is to extract silicon from a high-purity silicon crucible and then pull it into silicon single crystals through techniques such as the Czochralski method or zone melting. This step plays a crucial role in the performance of the cell, as the purity and crystalline quality of the single-crystal silicon directly affect the efficiency of electron flow.

Next, the silicon single crystal is cut into thin slices and undergoes multiple processes of surface treatment and photovoltaic cell preparation. In this process, photosensitive materials and metal conductive layers are used to form the key components of the solar cell. Each step requires high-precision equipment and strict quality control to ensure the performance and reliability of the final product.

The reason why manufacturing monocrystalline silicon solar cells is so complex is that every step is directly related to the performance of the cell. From the drawing of silicon single crystal to the assembly of batteries, every link requires a high degree of process control to ensure the performance indicators of the final product. This is one of the reasons why monocrystalline silicon solar cells enjoy a high reputation in the market.

In the era of pursuing sustainable development and clean energy, can monocrystalline silicon solar cells become the mainstream choice in the future? This question touches on many aspects, from environmental friendliness to its sustainability in future energy systems.

The manufacturing process of monocrystalline silicon solar cells is relatively clean and does not involve the emission of harmful substances. It has a relatively low environmental impact compared to some other solar technologies. In addition, because monocrystalline silicon solar cells have a relatively long life, their environmental impact during their life cycle is also relatively small.

As technology continues to advance, the manufacturing process of monocrystalline silicon solar cells is becoming more energy-efficient and environmentally friendly. The introduction of new production processes and materials makes energy consumption more efficient and reduces waste during production.

In terms of sustainability, monocrystalline silicon solar cells are expected to play a more important role in future energy systems due to their efficient energy conversion performance. Its high energy conversion efficiency means that more electricity can be generated in a smaller area, which has positive significance for solving the energy shortage problem and improving energy utilization efficiency.

Monocrystalline silicon solar cells have shown potential advantages in terms of their environmental protection, sustainability and contribution to future energy systems, making them the choice for a sustainable future.

English

English Español

Español Deutsch

Deutsch عربى

عربى