In the ever-evolving landscape of renewable energy, polycrystalline solar cells stand out as a beacon of innovation and efficiency. These cells are the bedrock of solar panel technology, playing a pivotal role in the transformation of sunlight into a clean, sustainable power source. To truly comprehend their significance, we delve into the intricate world of polycrystalline solar cells, exploring the underlying technology, their distinctive advantages, and the critical role played by suppliers in this dynamic and burgeoning industry.

Polycrystalline solar cells, as semiconductor devices, encapsulate the essence of harnessing solar energy through the integration of multiple crystal structures within a single cell. Unlike their monocrystalline counterparts, these cells are characterized by a cost-effective production process while maintaining competitive efficiency levels.

At the heart of the solar revolution, polycrystalline solar cells boast distinctive characteristics that set them apart in the competitive landscape of renewable energy technologies. A standout feature lies in their adaptability to various lighting conditions, rendering them a versatile choice for a myriad of applications. The manufacturing process involves casting silicon into molds, resulting in a mosaic of crystal structures. This not only facilitates cost-effective production but also contributes to the cells' resilience in real-world, fluctuating light conditions.

Moreover, the advantages of polycrystalline solar cells extend beyond their performance attributes to encompass sustainability and economic viability. Suppliers of these cells play a pivotal role in ensuring the quality and reliability of these components, as end-users increasingly prioritize sustainable solutions. This section aims to delve into the key characteristics that make polycrystalline solar cells a preferred choice, offering a nuanced exploration of the factors suppliers must consider to align with the evolving needs of the market.

Suppliers must navigate the delicate balance between scale and quality, meeting the demand for quantity while exceeding expectations concerning durability and environmental responsibility. This involves not only optimizing manufacturing processes but also incorporating sustainable practices into the supply chain. The imperative for suppliers is not merely to provide solar cells but to contribute to a broader vision of a sustainable and ecologically responsible future.

In the dynamic and competitive landscape of renewable energy, the selection of the right supplier is a decision of paramount importance for manufacturers and project developers.

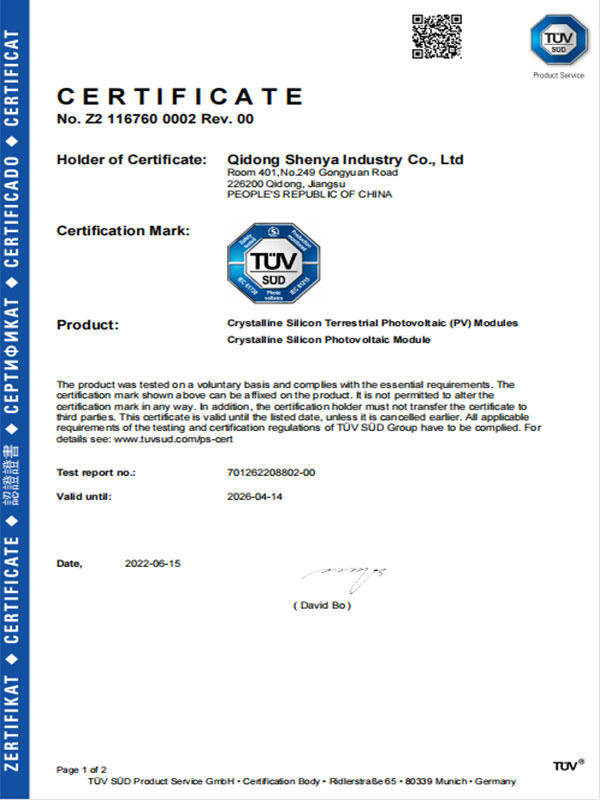

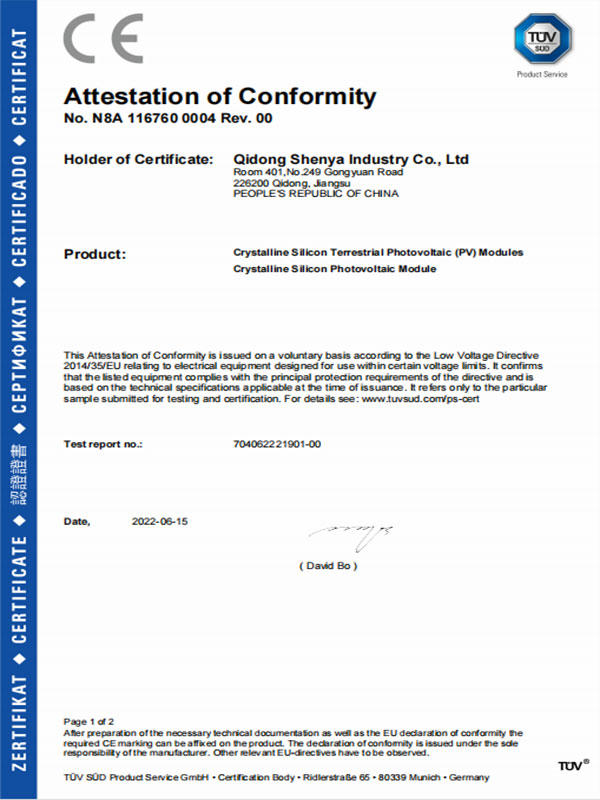

A critical exploration of case studies and industry trends reveals how suppliers are adapting to advancements in solar technology. This encompasses improvements in cell efficiency, reduced manufacturing costs through innovative processes, and the integration of smart technologies to enhance the overall performance of solar cells. Additionally, considerations like supply chain resilience, adherence to stringent quality standards, and global market reach will be scrutinized as crucial elements in evaluating the reliability of a supplier.

As the solar industry matures, collaborations between solar cell manufacturers and suppliers become integral to driving innovation and maintaining a sustainable supply chain. Beyond the technicalities, suppliers are now pivotal players in shaping the trajectory of solar energy by actively contributing to advancements in materials, production processes, and recycling initiatives.

English

English Español

Español Deutsch

Deutsch عربى

عربى